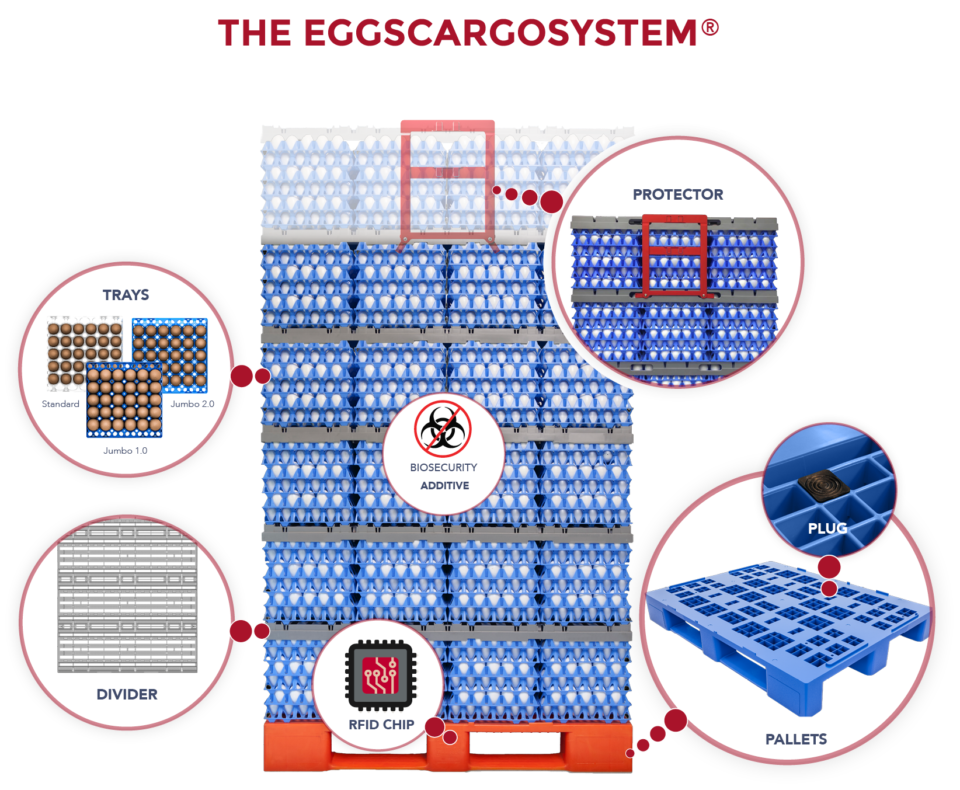

For over 20 years, the EggsCargoSystem® (ECS) has proven to be the best solution for egg transport. Invented in the Netherlands and manufactured in Italy, ECS® is the perfect joint venture with all the modern egg processing equipment.

Practice

The system can be used in different heights:

- for manual processing, a set with 1 pallet, 3 dividers and 288 trays is advised. This fits 8.640 eggs.

- for automated processing, the set can be expanded to 5 or 6 layers with space for 10.800 or 12.960 eggs.

Features

The three parts are produced in high quality virgin material, provided with UV stabilisation. The pallet, divider and trays are stably connected to each other due to their mutual design. Because of this firm connection, eggs are maximally protected. This results in <3% breakage.

All pallets contain a RFID chip that makes digital tracking and tracing possible. For easy identification ECS® can be produced in all RAL-colours. Also a personalised inscription on the 3 parts can be chosen.

Sustainable

Since its introduction, more than 280 million ECS® trays have been sold in more than 116 countries. The system is used daily by more than 1.000 customers. This is not only because of the safety for the eggs, but also because it optimizes the loading capacity. Due to its longevity and because it can be completely recycled, it can be considered the most sustainable system available on the market.

For more information, visit www.gi-ovo.com or send an e-mail to: sales@gi-ovo com