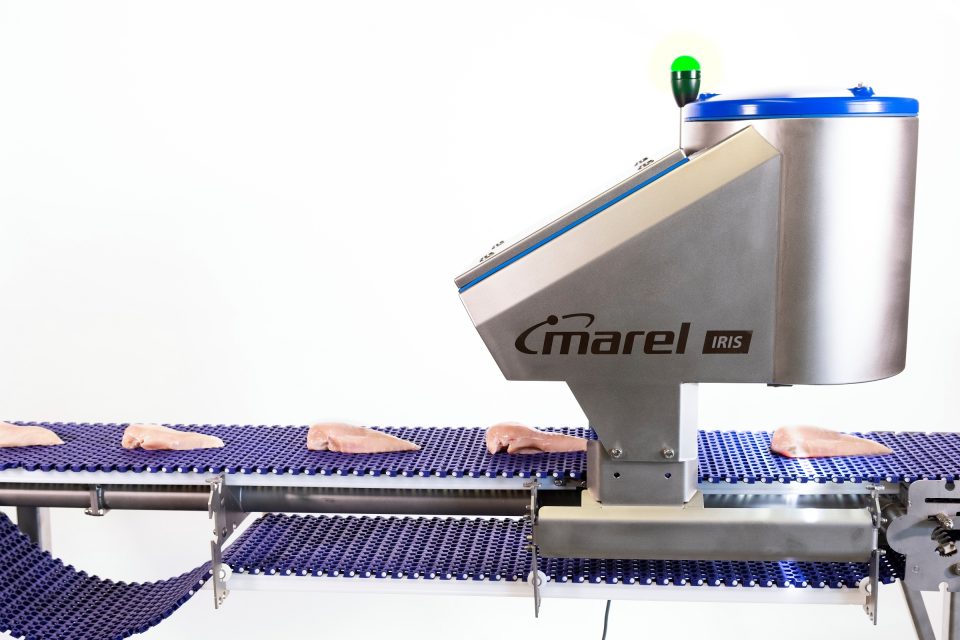

Besides having their fillets inspected for bone contamination, poultry processors are also eager to get some kind of automated fillet quality inspection. Marel’s IRIS FI (Fillet Inspection) camera offers such a visual quality assessment. Because of its ability to detect defects such as bruises, fat and skin, IRIS FI plays an essential role in supplying highest quality food.

A typical fillet line will feature a deboning system, a trimming station and a bone scanner. Additionally, IRIS FI offers the option to secure the visual quality.

Quality assurance

IRIS FI is an excellent tool for quality assurance. Installed after the trimming station, it can check in real-time whether the trimmed fillets, that are on the conveyor belt at that moment, meet the quality requirements of the customers.

One purpose of collecting data in this way is to assess the performance of the trimming process. Performance reporting can be done for many criteria, such as time, flock and defects that were in the line. It gives plant managers a reliable image of the trimming department’s operations. It is even possible to compare the different trimming tables.

If trimming is done too intensely, too much valuable meat weight will be downgraded. Too mild trimming can lead to customer complaints and a lower order intake. Either way, processors will lose money. To prevent this, it makes sense to instruct the trimmers exactly how to trim. The results of such a training can be verified by IRIS FI. In this way, processors can gain an incredible amount of valuable meat on an annual basis, representing several hundreds of thousands of euros.

Distribution options

IRIS FI can be combined with Innova PDS and a fillet distribution system, allowing to filter out the products that don’t meet the criteria. Trimmers could miss a slice of fat or cut off too much, leaving an odd-shaped fillet. Such products are unwanted in a retail tray and should be directed to a different process stream.

The camera and the software cooperate in assigning a certain quality to the fillets and this quality information can be used for decision-making for downstream distribution. In practice, this could be Marel’s Fillet Distributor solution, including the intelligent servo-operated conveyor belts which redirect products of different qualities to different processing streams. An upper belt could lead to a RoboBatcher or another tray packing process, while a lower belt could lead to a marination, shwarma-strip or schnitzel processing line.

Check in real-time whether the trimmed fillets meet the requirements of the customers

Exactly what does IRIS FI see?

Processors can choose their own IRIS FI settings to select poultry fillets of the best possible quality. It is easy to make the ideal recipe for the allowed tolerance threshold of individual bruises, total bruise area, fat defects and total fat area. Deviant fillet shapes can also be taken into account. Among the fat defects, residual skin –not removed by a skinner– is also detected. Detected bruises can be subcutaneous bleedings or blood clots –visible as sharp, red dots that can simply be wiped off.

As a result of inferior wing separation, the wing pit is notably a critical spot where several defects may occur, such as blood spots or remaining tendons. On the other hand, too enthusiastic trimming in this area will result in odd fillet shapes and too much good meat spoiled.

Individual or total defects

IRIS FI has a lot of integrated intelligence onboard. It knows, for example, that it should ignore the regular small stripe of fat in the middle of every fillet (except when it is oversized or bruised). Every single fillet is photographed. When needed, for analysis purposes for instance, all images can be stored on a server to be reviewed afterwards.

Detection settings of IRIS FI can be adjusted precisely, from very strict to more tolerant, just what the customer asks for. The area limits can be set for blood and fat independently. In any case, the Innova PDS software is able to register (and sort out) the fillets with defects that cover a larger surface than the delimited area, be it an individual defect or the total of defects.